End of The Line! The Story of Tucker #1050 (Part II)

By Mark Lieberman

The following article is an excerpt from the Tucker Topics magazine. To see Part 1 of the “End of the Line” series CLICK HERE.

This is the second part of the story that chronicles the incredible journey of the final production Tucker ’48 automobile. Tucker #1050

Now that Tucker #1050 has arrived at the Nostalgic Motoring Ltd. restoration shop, we were able to closely examine the car and learn the secrets that it has held for 75 years. Our initial objective was to service the systems and make the car operational. Secondarily, we will look at freshening some of the cosmetics. The first thing that we noticed was the paint color had been changed from its original Royal Maroon to a very attractive but non-factory medium crimson metallic. The interior had also been changed from its original tan (code 940) wool broadcloth to a nylon velour that had a distinctive 1980s appearance.

The original torsilastic suspension tubes had failed long ago but were still in place. As such, the suspension was riding flat on all of its bump stops. The engine was in its place and appeared complete. It rotated by hand and displayed the serial number 33598. This confirmed that this was the engine at was purchased at the Tucker auction along with 1050 by Ezra Schlipf. It also coincided with the final Tucker engine serial number recorded. That meant we had the final car with the final engine, AMAZING!

The paint had been refreshed while in the ownership of Curtis Foester and was still in remarkably great condition. Even though decades had passed since 1050 had been painted, it had never been operation and never driven. This along with museum level care had preserved the finish remarkably well. Other than a good cleaning and paint correction, we were able to leave the paint alone.

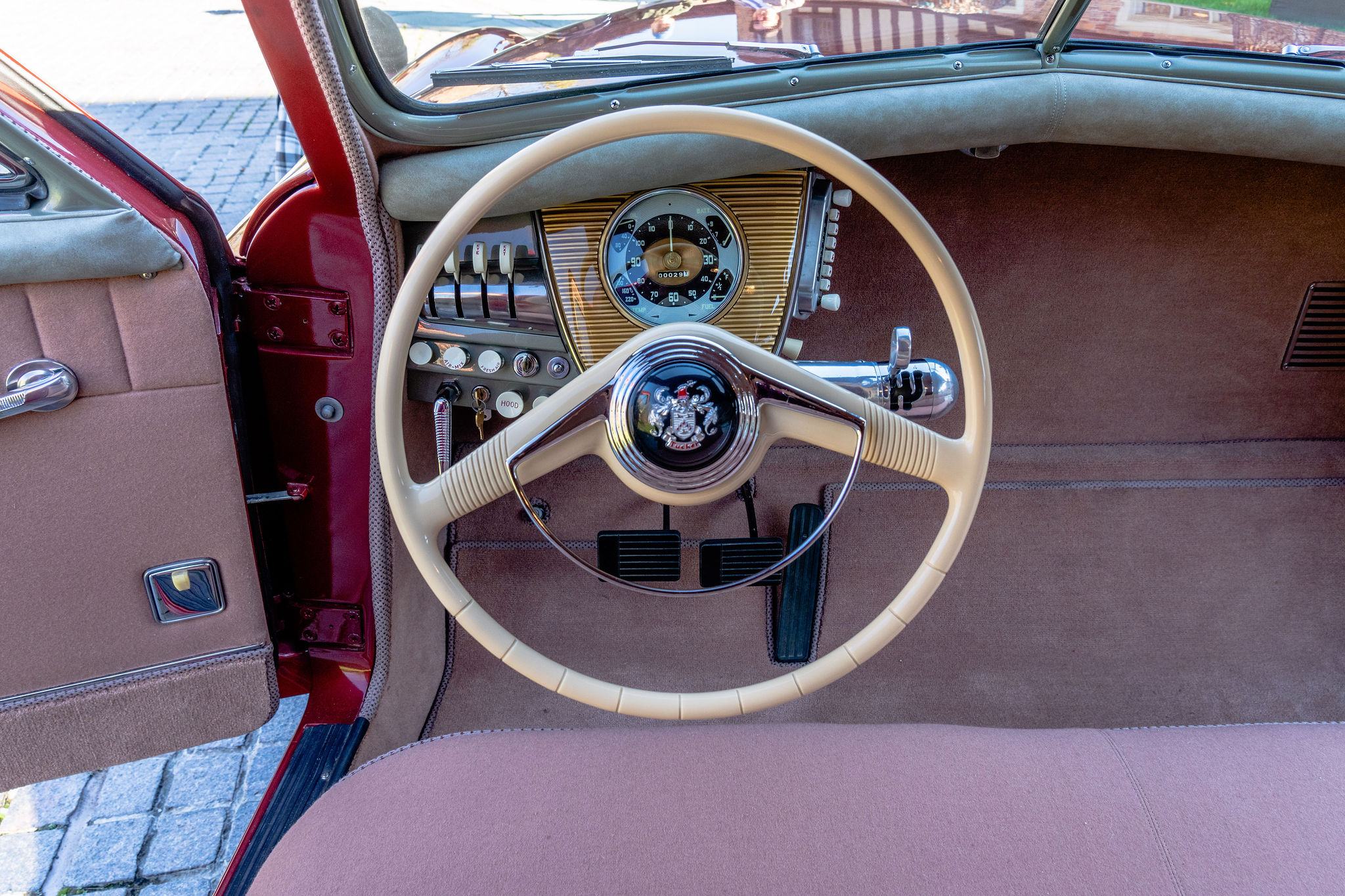

The interior had been redone earlier by Glen Prey. He also redid the interior of Tucker #1036. That car happened to be in our shop at the very same time. This allowed us to compare the finishes and materials used during the interior refreshing of both cars. Glen used an unusual color of sand beige paint on the window moldings and trim panels. Both of the cars matched exactly. The decision was made to replace the interior fabrics and carpet with the correct colors and materials. We would also strip and refinish the window moldings and interior trim with the correct factory color of grey metallic with a hint of green.

As we removed the seat covers from 1050s seat frames, we noticed that the seat frames had different structures to them as well as different sizes and location of the coil springs. They showed no signs of wear or compression. (That is a clear indicator of frequency of use/miles. On this car there was virtually none.) There are documents in the Tucker Cammack archives (in the AACA Museum) that discuss the factory experimenting with seat spring rates and configuration along with seating position to increase comfort and reduce driving fatigue. These seat frames further confirmed these writings. Furthermore, by virtue of the fact that these frames had different construction designs, it also indicated that these frames might have been the only remaining frames in the factory. Remember, by now the Tucker factory was largely out of parts. In fact, the folks assembling this car had to get even more creative as the build continued. The glove box door was stamped with the number 27. Yes, this door was scavenged from Tucker 1027, the car that rolled over during the testing at the Indianapolis Motor Speedway. We peeled the fabric from the outer door and sure enough, it was Waltz Blue, the color of car 1027. By commandeering parts from the crashed car it saved the crew valuable time and with only a handful of volunteers assembling the final cars, they didn’t have a full team to be fabricating parts that they could grab from another car. We discovered that the engine cover latching crossmember is also stamped 27.

As we continued to remove the remainder of the interior and related fabrics and trim, something quite extraordinary was reviled. We were looking at a perfectly preserved interior tub. Original floors, original spot welds, original stampings, no rust, no patch panels, it was amazing. This was a benchmark example to document and study as reference for future restorations. Following careful photography, measurements and documenting the details we restored the interior to its original livery, materials, stitch patterns and colors.

We next moved on to the fuel system. What was the inside the fuel tank going to look like? Theoretically, it should be pretty clean since there was no reason for it to have been holding fuel. We opened the tank up by removing the sending unit and peered in. It was like brand new! No rust or gummy old fuel. It was beautiful. It did have traces of fuel in it as someone had attempted to start it at one time recently.

Now on to the brakes…what brakes??? All of the fluid leaked out long ago, leaving the master cylinder and wheel cylinders dry, crusty and inoperable. The brake shoes were original with 1948 dates on them. They showed absolutely no signs of wear and in fact, had never seated to the drums. We were looking at new 1948 components. Rebuilding the hydraulic systems put the brakes back in proper operating condition.

The electrical system was quite interesting. It revealed a combination of original harness and some spliced in more modern modifications. This was clearly another facet of their attempt to get the car running. Another interesting discovery was the complete absence of the harness that controls the transmission. This is a stand alone harness that provides power to the solenoids that control the pre-select shifting mechanism. The absence of this harness along with the associated fasteners conclusively show that this component was never installed at the factory. This was more solid proof that the car was never functional before our commissioning. The solution was a complete replacement of the wiring harness with a properly constructed harness made to the original specifications.

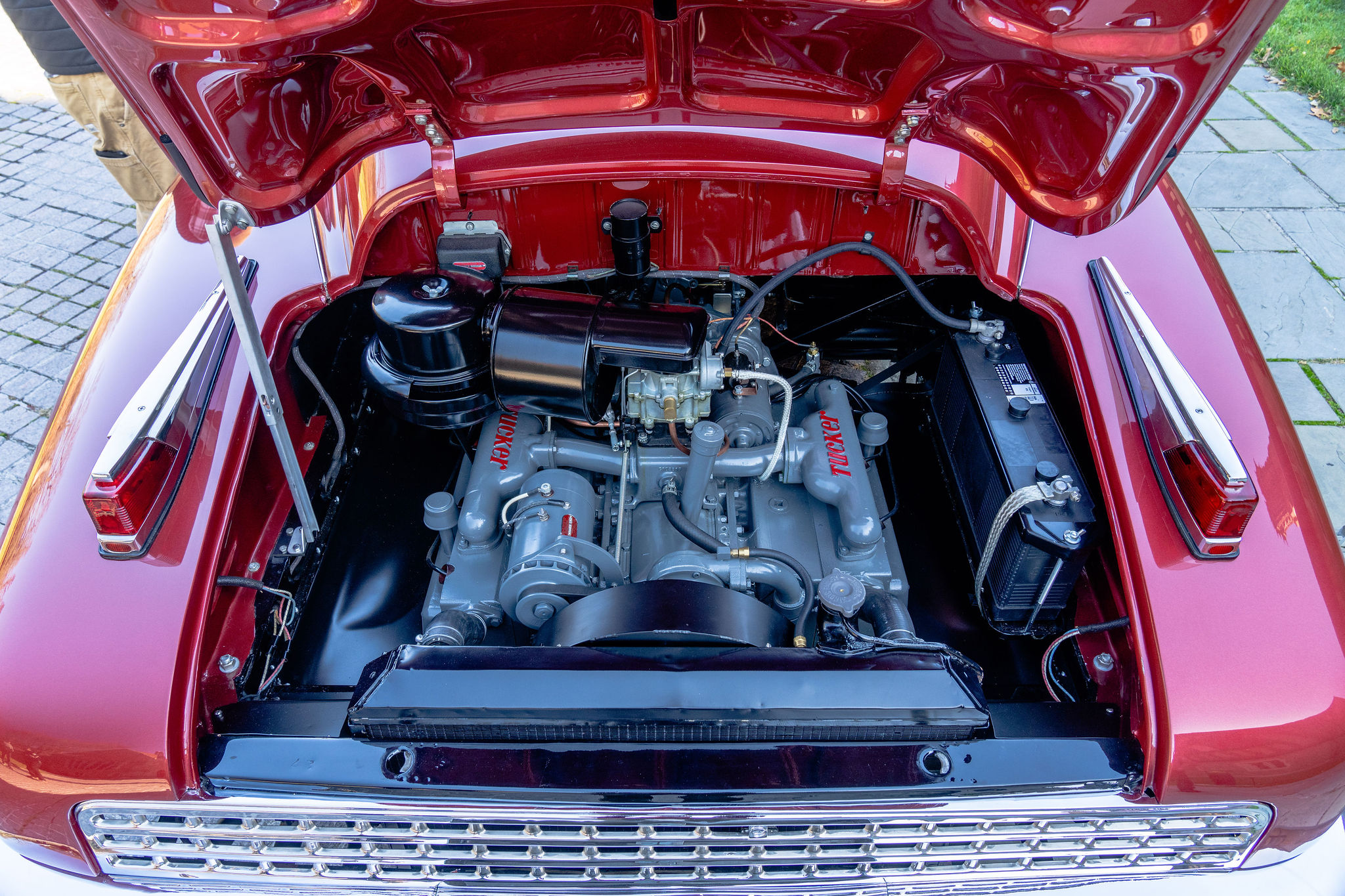

Now on to the engine! The first thing we did was examine the stamped engine number. This identified the engine as 33598. According to the factory build documents, that coincides with the final engine produced. It also corresponds with the purchase records of the engine purchased along with this car at the auction.

We oiled the cylinders, changed the engine oil and rotated the engine over by hand. It turned over smoothly but there was more to learn before we would try to start it. A bore scope inspection of the cylinders revealed some corrosion in 3 of the cylinders. Age and moisture had combined to damage the cylinder liners. Knowing that this might require major surgery, we would come back to this after we completed the inspection. We noticed that when we rotated the engine by hand, the water pump didn’t spin with the belt. It was locked in place.

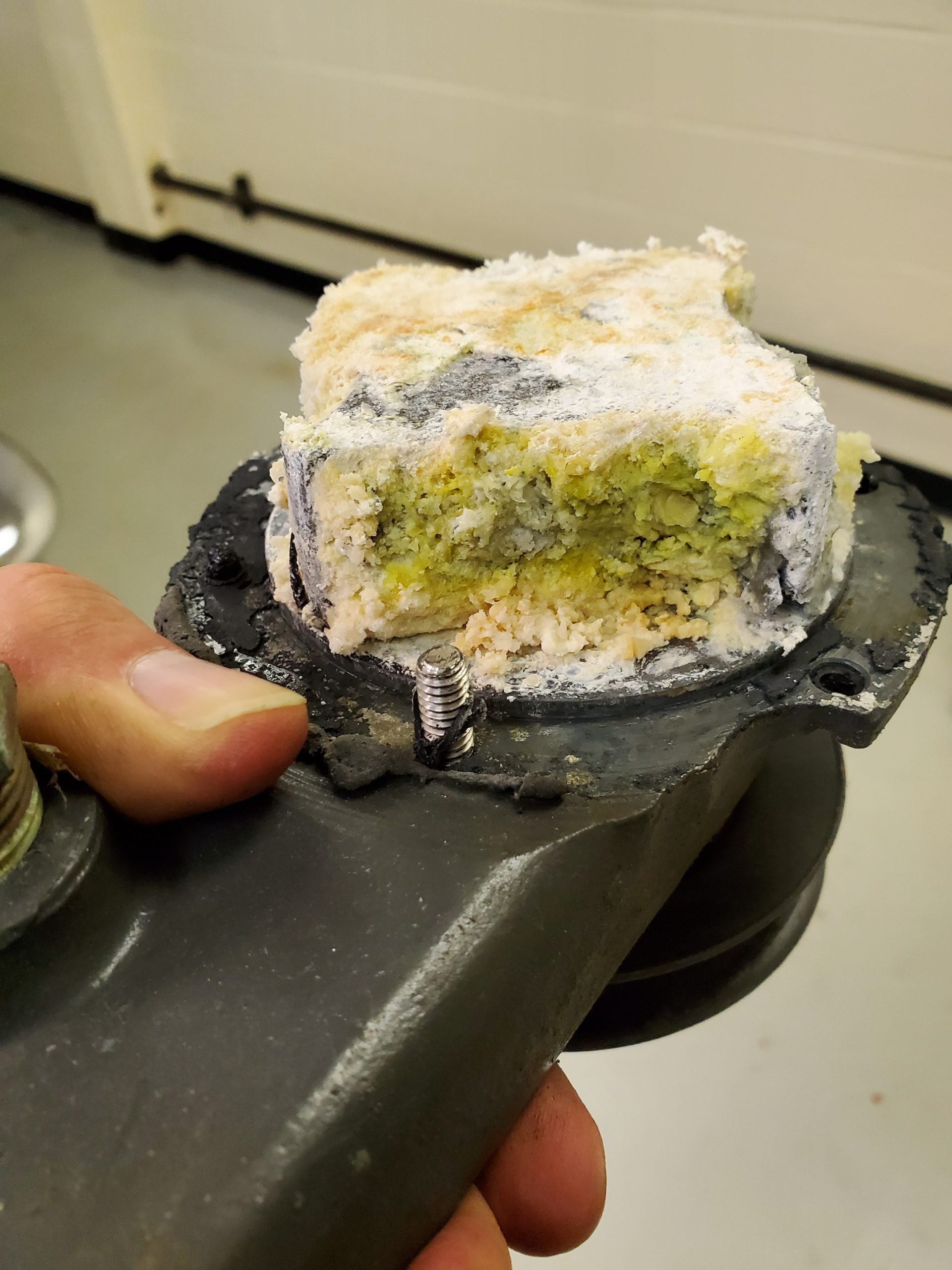

Removal of the pump revealed a condition that I have never seen in my 48 years of working on engines. The coolant had coagulated and crystalized into a solid mass. This created a new challenge. Has this condition spread throughout the cooling system, cylinder heads and cylinder jugs? If it had, how would we clean it out? This had to be as a result of a mixture of incompatible fluids. We began a series of experiments trying to determine what would dissolve the crystals. Fortunately, we were able to recover several large samples of the crystalized coolant to experiment with. By combining the chemicals in radiator flush and elevating the temperature, we were able to break down the clumped and crystallized coolant.

To insure we would get it cleaned out of every passageway, we would have to disassemble the engine and remove the cylinder heads and cylinder jugs. This would give us accessibility to every passageway and pocket. To complete the cooling system service, we boiled the radiator and flushed any crystalized coolant out of it as well. The process was completely successful and the castings cleaned up beautifully. This also gave us the opportunity to fully inspect the cylinder liners. We had already observed obvious signs of corrosion and this was the ideal time to address it. We replaced the cylinder liners and piston rings. Now the internals were fresh and should perform perfectly.

With the engine out, we serviced the ignition system, rebuilt the carburetor and painted the engine it its correct colors. The result allowed the engine bay to present as new.

Next was the transmission. The transmission in this car was of the Cord variety. About half of all tuckers have the Cord pre-select transmission. This transmission was installed in car by Auburn Cord Parts in the early 1980s as described in part 1 of this article. We removed the transmission from its resting place and opened it up for inspection. Unlike every other part on this car that showed absolutely no signs of wear, this did have wear. It had been used in another car prior to installation in 1050. As such, we disassembled it completely and rebuilt it with all fresh parts.

We replaced the original, failed Torsilastic tube suspension with the new tubes that we manufacture. This allowed the car the sit and ride as the factory originally intended. The Torsilastic tube suspension in these big cars provide a totally unique driving experience.

Once our refurbishment was complete we prepared for a historic drive. This would be the first time #1050 was ever driven, first time it was ever on the road and the first time it moved under its own power. What an incredible honor it was to be the first person to drive #1050. I was teaming with excitement and anticipation. Two of us climbed in for the inaugural drive. I turn the key and pressed the starter button. The engine came to life with a familiar growl. First gear was selected and we were off! As we accelerated down the street I noticed the speedometer displaying an accurate MPH but moreover, the odometer was alive and recording the first miles traveled. This is a moment we will remember FOREVER!.

At the time of this writing, #1050 has now travelled 30 miles. Everything is working correctly and it’s a very happy Tucker. This was an amazing experience. We were able to bring to life a car that has been quietly waiting for 75 years to wake up. We have now completed the work the Preston and the team at the Tucker factory started so long ago. The last of the original 50 Tucker ‘48s is now completed and fully operational.